Turret Punching Technology: The Endless Possibilities and Applications

When it comes to metal fabrication, few processes offer as much versatility and precision as turret punching. From custom fabrication to large-scale production runs, it's a fast, efficient solution for shaping sheet metal. Whether you're

A Comprehensive Guide to Understanding Different Types of Metals in Fabrication

Metals are fundamental materials used across a wide array of industries due to their varied properties and applications. From ferrous metals like steel and iron, known for their strength and durability, to non-ferrous metals such

Navigate Metal Laser Cutting with Acorn’s Seamless Partnerships

Efficiency and precision sit at the heart of metal fabrication, and at Acorn Metal, while we might not house laser cutting machines directly, our dedication to facilitating top-tier laser cutting services through trusted third-party providers

Metal in Architecture – Striking Structures and Designs

Architects rely on metal fabrication and manufacturing to shape the inner structures of their designs. From the towering skyscrapers that define urban landscapes to the intricate details adorning historical structures, the influence of metalwork throughout

6 Tips for Choosing the Best Metal Fabricator

Metal fabrication – the process of cutting, bending, punching and other methods of manipulating metal to create a metal structure or other product – is required to progress many modern projects and industries including aerospace,

The Advantages of Powder Coating

Unlike traditional metal painting methods that are applied as a liquid, powder coatings are applied in powder form. Usually, paint consists of a binder and a pigment suspended together in a liquid solvent. Powder coatings,

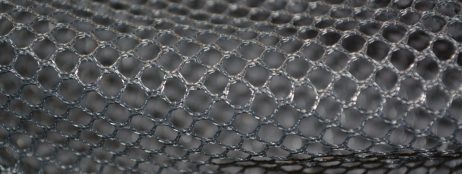

Different Uses for Perforated Metal

Perforated metal is a frequent sight in industrial and commercial settings, and it's also making its way into home decor. Because it protects and encloses rooms while still allowing for light, air, and visual appeal,

What Are Component Housings?

When designing and building any new custom electrical product, the focus tends to be on the often complicated inner workings. A key element that's sometimes overlooked is the safe storage and ongoing protection of these

Industrial Louvres, What They Do And How They Operate

Through exacting sheet punching production, here at Acorn Metal we have the machinery and experience to design and build the perfect industrial louver to fit your specific requirements.

Acorn Metal workshop extension

We are delighted to announce that we have recently finished building an extension to our already large workshop. These facilities, based in Malaga in the Perth suburbs, are designed to house state-of-the-art equipment to provide

Trends in the sheet metal and fabrication industry

Thanks to the constant technological advances the tools of the industry have become more advanced and effortless than ever, meaning it has never been easier to satisfy each customer's demand. Gone are the days of

Metal Bending and Turret Punching

Here at Acorn Metals, we’re experts at CNC bending. We produce high-quality fabricated metal components that are equipped for the production of numerous metal manufacturing products, and CNC bending is one of our biggest services.