Fabrication Utilising The Latest CNC Turret Punch Technology in Perth, WA

CNC turret punching is a fast, efficient, and cost-effective way to cut, perforate, and form sheet metal with unmatched accuracy.

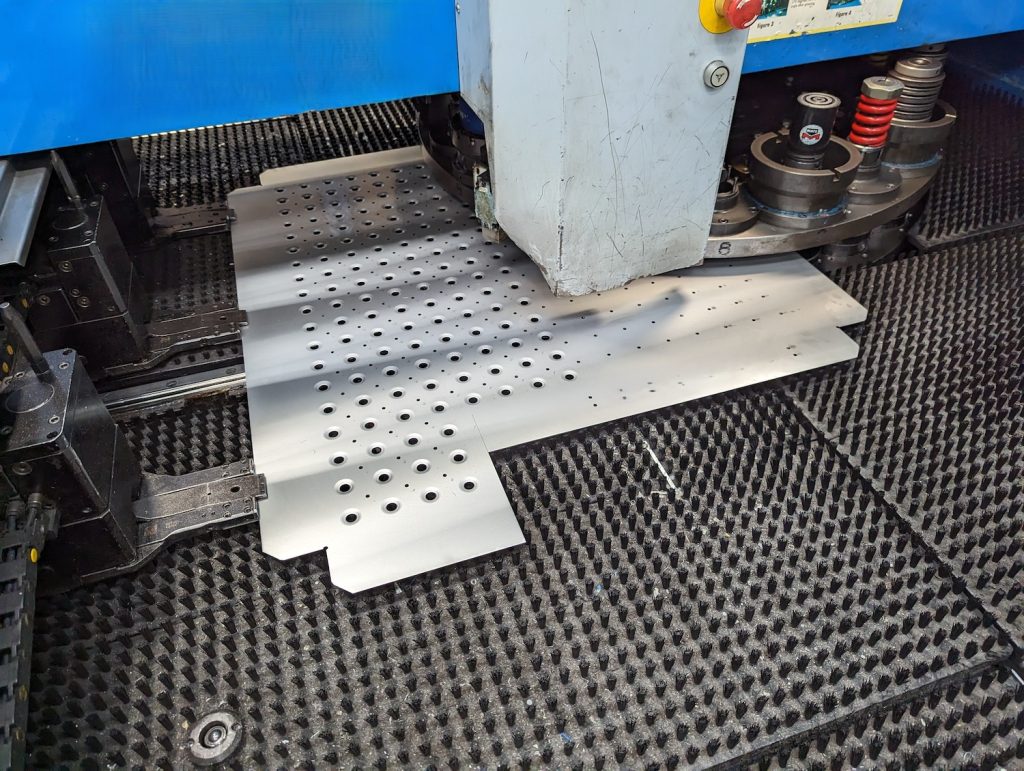

At Acorn Metal, Our two 30T Finn-Power turret punching machines boost production efficiency with fully automated loading and unloading, ensuring fast, repeatable, and accurate processing.

These machines are capable of handling all metal types and sheet sizes over 3000mm long, with a maximum working width of 1500mm.

They excel in perforating, embossing, forming, and producing louvres, dimple plates, tread plates, hooks, tabs, and more. With unmatched speed, consistency, and precision, they efficiently blank small parts, making them ideal for high-volume production and custom fabrication projects.

What Is Turret Punching?

A CNC turret punching machine is a high-speed metal punch press that uses computer-controlled punch tooling to create holes, slots, dimples, cutouts, and complex shapes in sheet metal. These CNC punch press machines work by rotating a turret loaded with multiple punch tools. This offers a faster and more cost-effective alternative to laser cutting for repetitive patterns, perforations, and formed features.

At Acorn Metal, our two 30T Finn-Power CNC turret punch presses with 30-tonne capacity are capable of:

- Processing sheets up to 4000mm x 1500mm

- Handling mild steel, stainless steel, aluminium, and other metals

- Running fully automated loading and unloading for efficiency

- Consistent accuracy for small-batch prototyping and large-scale production

- High-speed perforation with minimal material waste

- Advanced forming options including embossing, louvres, extrusions, and dimples

- Customisable patterns tailored to specific design requirements

The CNC Turret Punching Process at Acorn Metal

Our turret punching machines handle everything from basic hole punching to multi-stage forming with precision and efficiency.

- Material Loading: Sheet metal is loaded into the Finn-Power 30T turret punch and positioned for cutting.

- Tool Selection: Multiple tool stations select the required hole shapes, cutouts, and forming tools.

- Machine Programming: CNC controls adjust speed, pressure, and precision settings based on material type and thickness.

- Punching Execution: The turret press punches, cuts, perforates and forms the metal to exact specifications.

- Inspection & Finishing: Each component is checked for dimensional accuracy, edge smoothness, and compliance with design specs.

- Post-Processing: Parts are organised for bending, welding, assembly, or surface finishing as needed.

Our turret punching machines run fully automated, ensuring high speed, reduced waste and repeatable quality across all projects.

Capabilities of Our Finn-Power 30T Punching Press

At Acorn Metal, our Finn-Power 30T turret punch presses provide unmatched versatility in sheet metal fabrication.

Punching & Cutting Capacity:

- Up to 3mm mild steel or similar

- Up to 3mm stainless steel

- Up to 5mm aluminium, brass, and copper

Workable Sheet Size:

- Maximum: 4000mm x 1500mm

Advanced Features:

- Hole Punching: Creates precise cutouts in various shapes and sizes, ensuring clean edges and accuracy.

- High-Speed Marking & Engraving: Uses a diamond-tip scratching tool to etch serial numbers, logos, or identification markings.

- Embossing: Forms raised surfaces in the metal for added texture, durability, and decorative appeal.

- Dimples: Creates recessed areas in sheet metal to add strength and rigidity without increasing weight.

- Louvering: Forms ventilation openings directly into the metal for airflow, cooling, and heat dissipation.

- Piercing: Produces precise perforations by puncturing the metal.

- Recessing: Indents specific areas in the metal for countersinks, fittings, or flush-mounted components.

- Extruding: Stretches material around holes to create raised edges that reinforce structural integrity, ideal for creating a hole to be threaded in light gauge material.

- Coining: Imprints fine details, patterns, or text into metal with extreme accuracy and repeatability.

- Tapping: Cuts internal threads into pre-punched holes, allowing secure fastening without additional inserts.

- Forming: Shapes metal by bending or contouring it for structural applications and custom designs.

- Nibbling: Uses a series of overlapping punches to cut intricate shapes and non-standard geometries.

Our two turret punch presses are optimised for small-batch prototyping and high-volume production, ensuring efficiency, repeatability, and accuracy in every project.

Applications of CNC Turret Punching

CNC turret punching is widely used across multiple industries, providing high-speed, cost-effective solutions for manufacturing, construction, automotive, and industrial applications.

Common Applications:

- Privacy Screens: Custom perforated panels for residential and commercial use

- Air Vents & HVAC Grilles: Precision ventilation components

- Machine Guards: Industrial safety panels

- Perforated Metal Signage: Custom branding and wayfinding panels

- Shelving & Racking Systems: Lightweight and durable storage solutions

- Lighting Diffusers: Perforated metal to optimise light dispersion

- Perforated Walkways & Flooring: Non-slip industrial and commercial surfaces

- Vehicle & Trailer Flooring: Durable, ventilated flooring for transport applications

- Outdoor Furniture: Metal components for benches, tables, and urban seating

- Security Doors & Window Screens: Reinforced perforated metal for added safety

- Acoustic Ceiling Baffles: Sound-dampening perforated panels

- Decorative Cladding: Stylish metal coverings for architectural applications

- Industrial Sieves & Screens: Used for material separation in food, mining, and manufacturing

- Automotive & Rail Panels: Custom perforated components for vehicles and public transport

- Server Cabinets & Racks: Airflow-optimised panels for data centres

- Electrical Enclosures: Custom-cut metal boxes for electrical housing

- Network & Telecom Cabinets: Secure metal enclosures for communication infrastructure

- Control Panels & Consoles: Custom-fabricated control panel casings

- Battery Storage Cabinets: Ventilated enclosures for safe energy storage

Materials We Work With

Our CNC turret punching machines handle a wide range of sheet metals, including:

- Mild Steel & Stainless Steel (0.55mm up to 3mm)

- Aluminium, Brass, Copper (0.55mm up to 5mm)

- Composite Panels, Polycarbonate, Polypropylene (Specialty applications available)

For unique materials or coatings, our team will assess best fabrication methods to achieve the required result.

Customisation & Design Considerations

- Custom Designs: Clients can submit CAD files, work with our team on custom designs, or request standardised patterns for their projects.

- Multi-Stage Forming: Our turret punch machines can handle multiple forming processes in a single setup, reducing lead times and improving efficiency.

- Batch & High-Volume Production: One of our machines is ideal for small-batch prototyping and intricate parts, while the other is designed for large-scale production runs.

Why Choose Acorn Metal for CNC Turret Punching?

- State-of-the-Art Machinery: Fully automated Finn-Power 30T turret punch presses

- High-Speed & Cost-Effective: Fast production times with minimal waste

- Precision & Repeatability: Consistent accuracy across all production runs

- Custom Solutions Available: Work with our team for custom patterns & forming

- Integrated Fabrication Services: Combine turret punching with bending, welding, or assembly for a complete solution

Whether you need custom perforations, precise cutouts, or high-volume metal punching, Acorn Metal delivers quality, efficiency, and reliability.

Contact Us for More!

Need high-quality CNC-punched metal components? Contact Acorn Metal today to discuss your project requirements. Our team is ready to provide expert guidance, fast turnaround times, and tailored solutions to suit your needs.

Call Us or Request a Quote Online to get started!