Strong and Cost Effective Fastening Solutions for Sheet Metal Assemblies

Self-clinching metal fasteners are durable, permanent, and cost-effective parts used for assembling sheet metal. At Acorn Metal Products, we use industry-leading machinery to apply self-clinching fasteners in various applications, including construction, automotive, manufacturing, and appliances.

What are Self Clinching Fasteners?

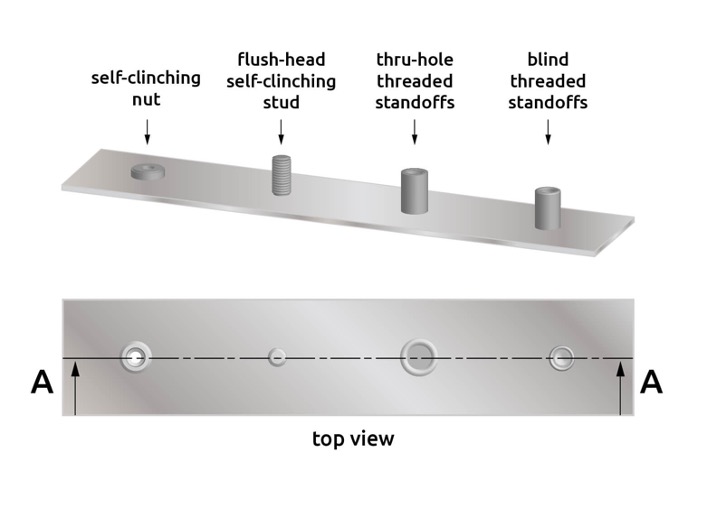

Self-clinching fasteners are a special type of bolt, nut, or pin that lock themselves into sheet metal when pressed in, unlike traditional bolts and nuts that come loose and need to be secured together. Applied using a heavy-duty hydraulic press machine, these style fasteners are more efficient to install than traditional fasteners and are highly secure, durable, and permanent. There are several types of self-clinching fasteners, including studs, nuts, pins, and standoffs.

Different types of Self Clinching Fasteners

- Studs: shaped like a traditional bolt, these self-clinching studs pierce through a metal sheet and act as a threaded post for other components to be attached to while remaining flush on the other side of the material with the elimination of a traditional bolt head.

- Nuts: a self-clinching nut or ‘clinch nut’ is similar to a traditional bolt, it offers a threaded hole for other components to be attached to and is pressed into the sheet metal, eliminating the need for taping a threaded hole or welding on a captive nut.

- Standoffs: a standoff is secured to a metal panel and offers a post for a second panel to attach to, creating a separation space between the two panels. The fixed gap can offer vibration resistance, airflow, and insulation.

- Panel Fasteners: Panel fasteners are used to securely attach panels to another surface. Panel fasteners differ from traditional bolts and nuts in the sense that they allow for the panel to detach easily, where frequent removal may be required.

- Pins: shaped like a bolt, self-clinching pins pierce through a metal sheet and can be used as a pivotal point, or for alignment between materials. Unlike traditional bolts, they are smooth and do not have a thread.

Advantages of Self-Clinching Fasteners

- Quick and Easy Installation: because self-clinching sheet metal fasteners lock themselves into the material they’re being applied to, additional bolts and nuts are not required. The fasteners are installed using a simple press which reduces the amount of time that each one takes to install.

- Permanent and Secure: the bond between the metal fasteners and the metal sheet is extremely strong, making them a permanent solution that’s highly durable.

- Minimal Maintenance: unlike traditional bolts and nuts which tend to require tightening over time, self-clinching fasteners do not need to be retightened as they are permanently fixed.

- Flush Finish: certain types of self-clinching fasteners are designed with heads that sit flush with the sheet metal surface, leaving a smooth, seamless appearance. This can also prevent snagging or interference with other components.

- Cost-Effective: due to the easy installation process and the elimination of additional components such as nuts and bolts, self-clinching sheet metal fasteners are a cost-effective solution.

Capabilities of Our High-Force Fastener

Self-clinching metal fasteners require a high level of force when they are applied to sheet metal so that they can effectively ‘clinch’. When pressed, the self-clinching fastener forces the sheet metal to knurl around it, creating a permanent locked-in bond between the two components. This requires powerful heavy-duty machinery.

Our Haeger 824 is one of the most advanced machines of its type, it’s used for applying sheet metal fasteners and is capable of high-volume production depending on the job requirements.

Force Strength

- Up to 8 tons of ram force (72kN)

Press Depth

- Up to 24 inches of throat depth (610mm)

- Adjustable retract position

Cost Effective

- High reliability, time efficiency, and energy efficiency reduces costs

Industry Applications

At Acorn Metal Products, we serve sheet metal and self-clinching fastener solutions to the following industries:

- Construction: metal framing, HVAC systems, roofing.

- Automotive: body panels, structural components, door assemblies.

- Manufacturing: sheet metal assemblies, electric equipment, appliance manufacturing, racking and storage systems.

- Appliances: mounting, heat shields, panels.

Your Sheet Metal Assembly Needs Met Here

At Acorn Metal Products we service a range of metalwork applications and have the expertise to fulfil your assembly proposals to the highest standard. Speak to one of our metalwork professionals today if you have any questions about self-clinching fasteners or any of our other metal fabrication and assembly services.