When it comes to the equipment that is needed to get your products manufactured accurately and efficiently, we have everything required here in our extensively equipped metal workshop. From benders and formers to turret punches and fastener inserters, we have invested in the best so that the results cost you less.

High Quality Equipment for Metal Manufacturing in Perth

Amada CNC-controlled benders

Our Amada CNC-controlled benders have the highest precision and accuracy for repetitive manufacturing with a large range of segmented tooling. At Acorn Metal Products, CNC sheet metal bending is delivered accurately to your specifications.

- Amada HDS 8025NT– 80 tonne x 2600mm Bend length

- Amada HDS 1303NT – 130 tonne x 3200mm Bend length

- Amada EG6010– 67 tonne x 1350mm Bend length

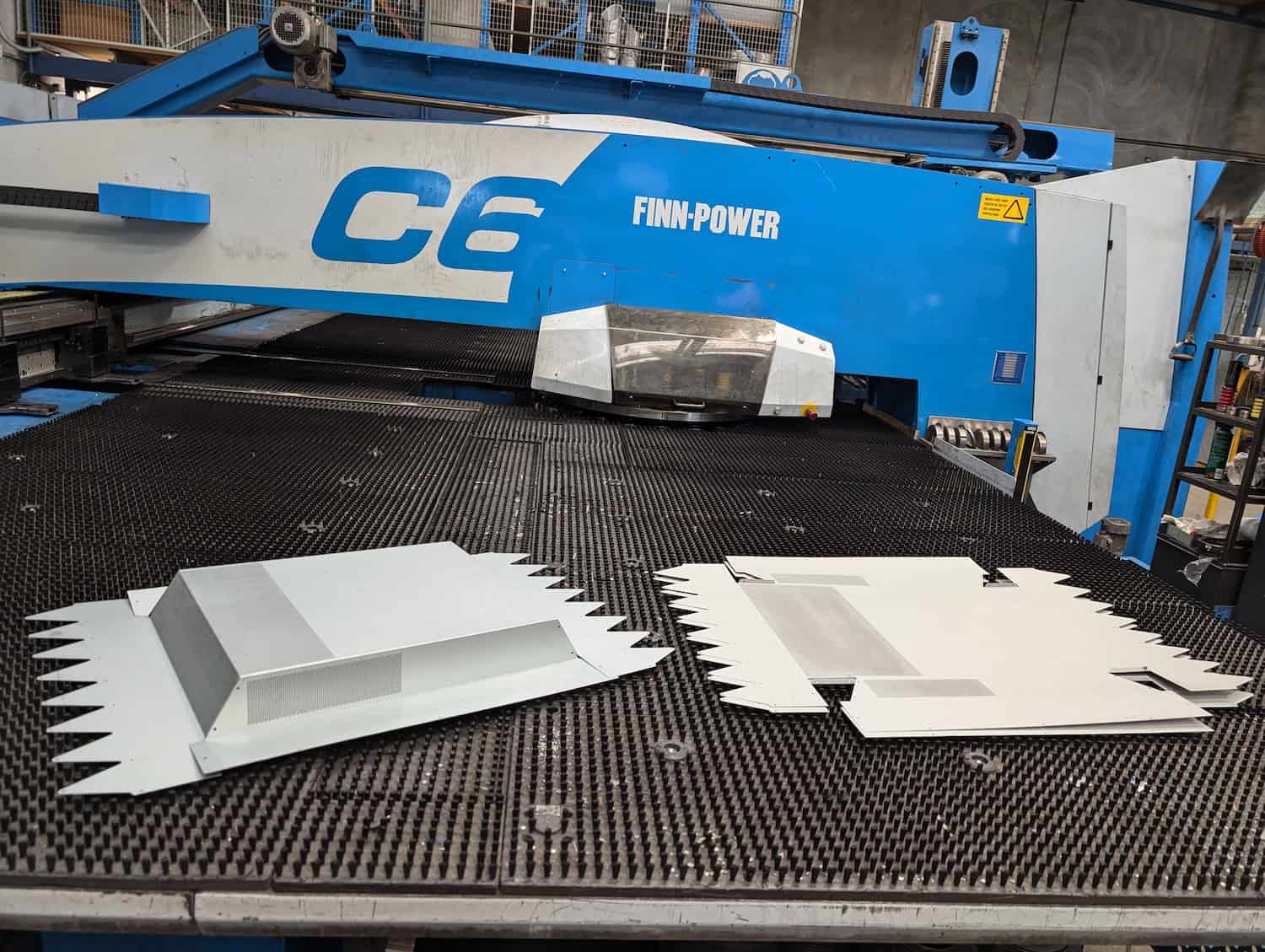

Finn-Power C6 Compact Express

We use the Finn-Power C6 Compact Express with automatic sheet loading facilities and brush tables for metal turret punching. The Finn-Power C6 is designed for efficient metal turret punching and creating shapes in a wide range of materials. Its automatic loading system also contributes to higher efficiency and reduced downtime.

- Material Capacity: 3600mm x 1500mm sheet sizes and up to 3mm thick steel / Stainless-steel and 5mm aluminium thickness

- Punching Capacity:30-tonne capacity

- Automation:Compact Express includes an automatic loading and unloading system

- Versatility:Suited to a variety of metals and materials

|

|

Finn-Power F5 turret punch with brush tables

The Finn-Power F5 turret punch offers significant advantages when working with smaller production runs with complicated processes.

- Material Capacity:3000mm x 1200mm up to 6mm thick sheet size

- Punching Capacity:30-tonne capacity

- Servo-Hydraulic Ram:The F5 uses a servo-hydraulic punching stroke that maximises accuracy and efficiency

Amada Togu III automatic grinding machine

The Amada Togu III ensures that our tooling used in turret punch presses is kept at an optimum level.

- Automation: The machine is fully automated, eliminating the need for a grinding operator

- Compatibility: It is designed to accommodate a wide range of thick-style turret tools

Haeger fastener insertion machine

With our Haeger fastener insertion machine, we have the technology for the insertion of all types and sizes of self-clinching fasteners. They are designed to automate and improve the efficiency and quality when installing hardware.

- Tooling Versatility:It is compatible with a large variety of tooling and has a quick-change tooling feature, which simplifies setup

- Speed Capacity:The machine uses high insertion speeds that increase efficiency

- Versatility: With a huge library of inserts and accommodating tooling

Madison 8 x 3200 Hydraulic Guillotine

The Madison 8 x 3200 Hydraulic Guillotine is designed to produce clean, straight, and precise cuts on sheet metal and a variety of materials.

- Shearing Capacity: 3mm for mild steel and stainless steel. 5mm for aluminium

- Cutting Length:The maximum cutting length is 3200mm

- Back Gauge Travel: 800mm for precise positioning

Forstner Sheet Metal Decoiler

The Forstner Sheet Metal Decoiler holds and unwinds large coils of sheet metal and prepares it for processes with a cut to length line while ensuring the material de-coils flat.

- Coil Capacity: Up to 1220mm width, 1.2mm thickness and 2 tonnes

- CNC Controlled: The machine is integrated into a larger CNC system that allows for precise uncoiling

Spot Welding Machine

Our light-gauge spot welders are designed to create reliable, durable bonds for sheet metal assemblies.

- Material Capacity: Our spot welding works best with stainless steel, mild steel, and pre-coated steels

- Control Systems: Light-gauge spot welders have advanced control systems that allow for precise pressure exertion and adjustments

- Automation:The machine is extremely automation-friendly, which allows it to be seamlessly integrated into automated production lines

Q-Fin Surfacing Range

Our Q-Fin Surfacing machines are made for deburring and grinding, providing high-quality finishes on final products.

- Multiple directional deburring and surface etching

- Wet Extraction System (WES):The machine uses a liquid coolant to capture and contain grinding dust, creating a cleaner and safer environment

- Non-Directional Finish: Q-Fin machines are designed to allow a directionless finish, ideal for applications where no distinct lines or patterns are desired

- Automation:The machine is extremely automation-friendly, which allows it to be seamlessly integrated into automated production lines

Call Perth’s most equipped metal workshop now on 08 9248 8888.