Acorn Metal’s commitment to excellence and expertise in metal fabrication shines through in our latest project—a small bracket complete manufacture. Despite the seemingly modest nature of this project, Acorn Metal’s attention to detail and dedication to quality transformed simple brackets into reliable and durable components. Witness the craftsmanship that Acorn Metal brings to even the most intricate projects.

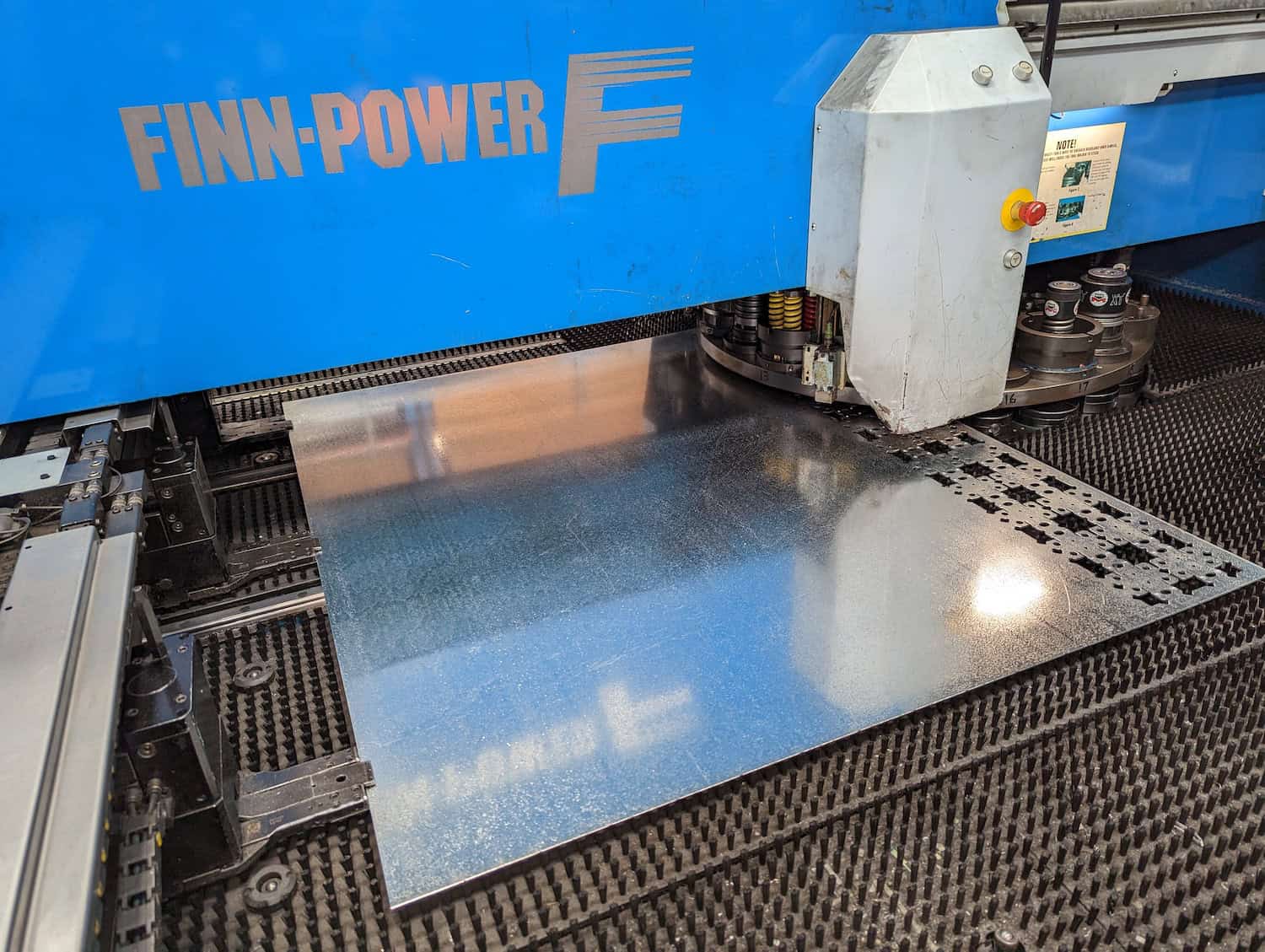

Turret-Punching for Precise Shapes

The journey of manufacturing these small brackets began with the use of turret-punching machines. Acorn Metal utilised these cutting-edge machines to precisely punch the required shapes onto the sheet metal. The meticulous turret-punching process ensured that each bracket component was flawlessly formed, setting the stage for the subsequent manufacturing steps.

Deburring for a Smooth Finish

After turret-punching, Acorn Metal focused on deburring the brackets. Deburring involves the removal of any rough edges or imperfections from the metal components. By meticulously smoothing out the edges, Acorn Metal ensured that the brackets were not only visually appealing but also safe to handle.

Metal Bending for Structural Integrity

With the precisely punched and deburred brackets in hand, the next step was metal bending. Through specialised machines, the team was able to manipulate the metal components and transform them into the desired shapes for optimal structural integrity. The bending process, guided by our teams’ expertise, ensured that each bracket was strong, durable, and capable of withstanding its intended use. The fusion of craftsmanship and functionality was integral to the success of this project.

Pristine Finish with Powder Coating

To give the brackets a flawless and long-lasting finish, Acorn Metal employed the technique of powder coating. The powder coating enhanced the brackets’ visual appeal and provided an added layer of protection against corrosion, extending their lifespan and ensuring they maintained their appearance even in even the most demanding environments.

Assembly for Ready-to-Use Brackets

The final stage of the manufacturing process involved assembling each bracket. Acorn Metal joined the various components, ensuring a precise fit and alignment. The attention to detail during assembly guaranteed that the brackets were ready to be used by the client immediately upon delivery.

This project highlights Acorn Metal’s ability to excel in even the most intricate and seemingly modest manufacturing tasks, showcasing its commitment to excellence in every aspect of its work. Whether it’s large-scale projects or small-bracket manufacture, Acorn Metal continues to be the trusted partner for custom metal fabrication needs, combining craftsmanship, attention to detail, and client-centric solutions.