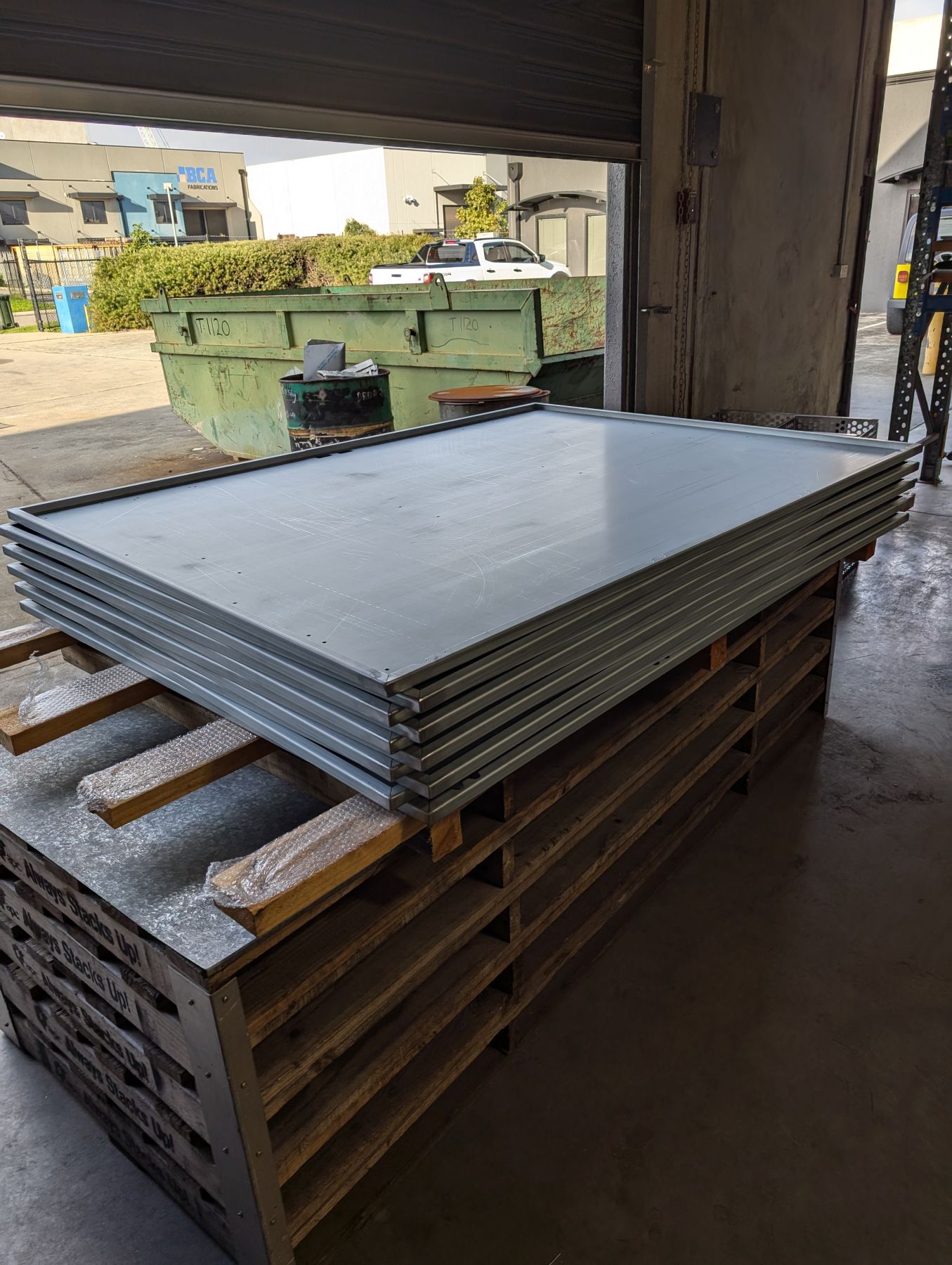

At Acorn Metal, we pride ourselves on delivering precision metal fabrication for projects of any scale. This recent project involved large-scale production of simple yet essential assembly components, demonstrating our ability to handle repetitive, high-volume work while maintaining exceptional quality.

Scope of Work

Our team expertly managed the entire fabrication process, combining multiple services to deliver precision and consistency for this high-volume project. The key steps included:

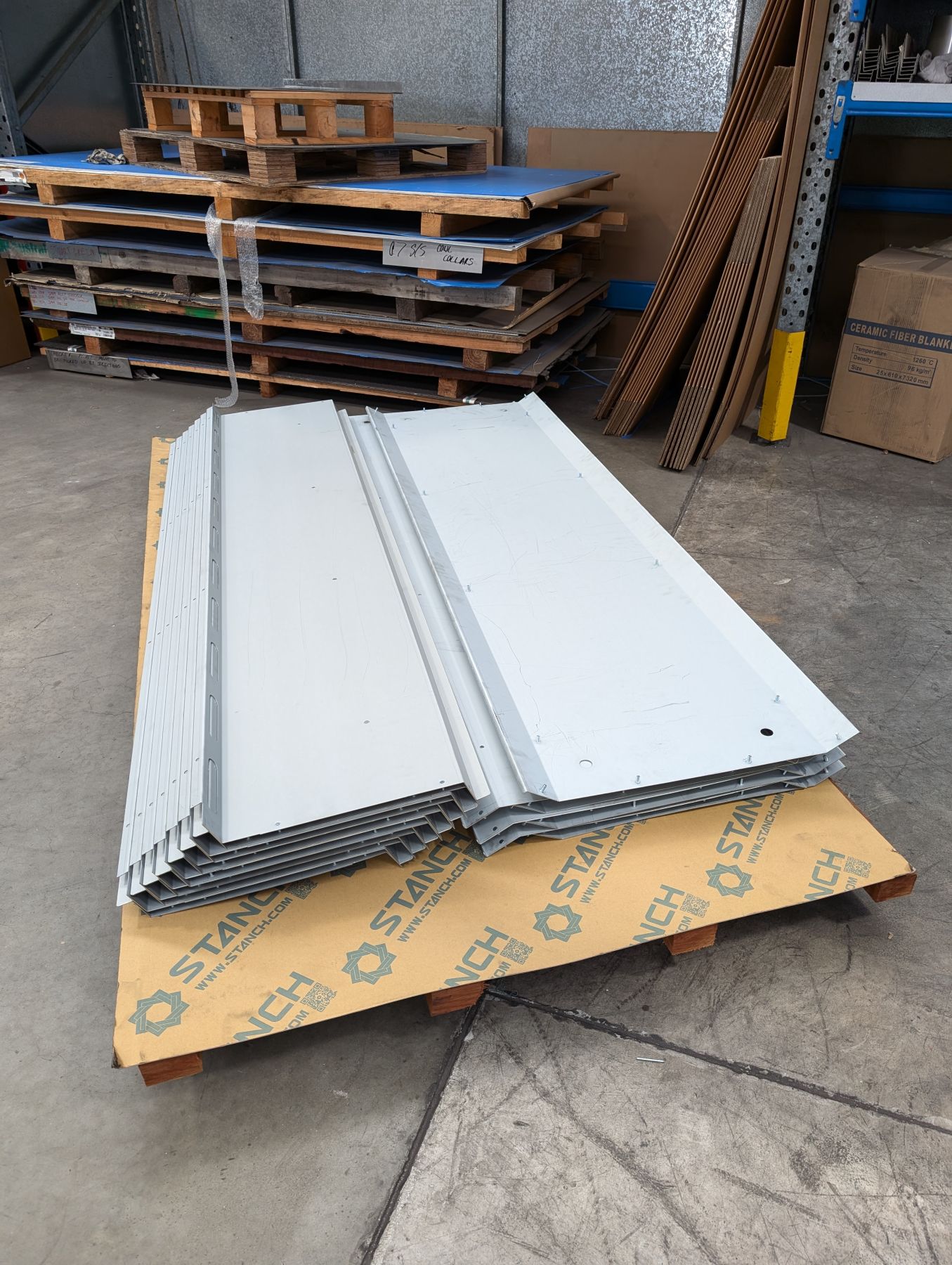

- Cutting: Using advanced guillotine shearing machinery, we accurately cut sheet metal into precise lengths and dimensions. This ensured clean, burr-free edges with consistent quality across all components.

- Punching: Our turret punching machines perforated the sheet metal with high-speed precision, creating holes, slots, and patterns as required. This process allowed for excellent repeatability and efficiency for large-scale production.

- Bending: Our press brakes handled the bending process, producing consistent folds and intricate profiles where required. With tight tolerances and a focus on accuracy, we ensured each part seamlessly met design specifications.

- Welding: Welding processes, including spot welding, were applied to secure joints and reinforce structural strength. This ensured the components were durable, dependable, and built to last.

- Assembly: Once individual components were fabricated, they were carefully assembled with meticulous attention to detail. This stage ensured all parts aligned perfectly, meeting functionality requirements for the final product.

- Powder Coating: The project was finished with a high-quality powder coating process. This not only enhanced the appearance with a smooth, professional finish but also provided additional protection against wear, corrosion, and environmental factors.

Key Highlights

- Large-Scale Efficiency: This project showcased our ability to manage repetitive tasks and large production volumes with ease.

- End-to-End Solutions: From raw sheet metal processing to the final powder-coated assembly, Acorn Metal oversaw the entire process.

- Versatility: The project highlighted our expertise in delivering high-quality components across multiple fabrication techniques.

Our team remains committed to providing tailored metal fabrication solutions for clients across diverse industries. Whether it’s a small custom job or large-scale repetitive production, Acorn Metal delivers results that stand the test of time.

Looking to streamline your next large-scale project? Reach out to the experienced team at Acorn Metal today to discuss your fabrication needs.