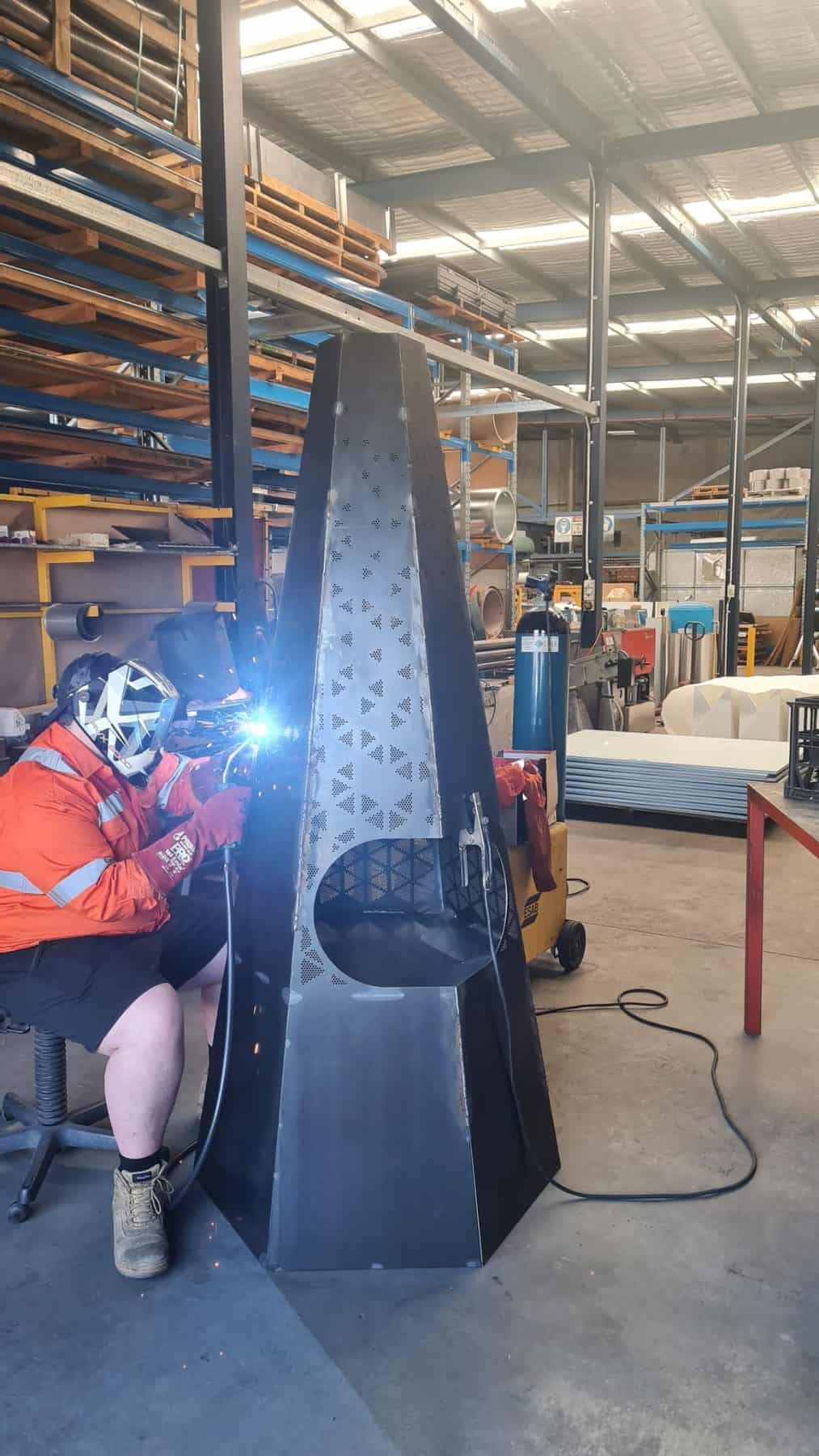

We recently completed a project that combined aesthetics with function. The custom fire pit we were tasked to create from our client’s awesome design had to not only safely house a fire, but to look great while doing so.

We placed special emphasis on perforation design, exploring layouts that would cast intricate shadows and allow firelight to glow through. Every cut was considered not just for function, but for the way it would interact with heat, light, and movement once in use.

The fabrication required a range of machinery and processes to take us from sheet metal to the final product.

Sheet Preparation

We started with heavy-gauge sheet metal, which was cut to size on our hydraulic guillotine. We were able to facilitate straight cuts with consistent accuracy across the main body panels and base plate.

Turret Punching

Before forming, we used our CNC 30T turret punch to create the detailed perforation patterns visible on the fire pit’s outer panels. The turret punch allowed us to make consistent perforations across the sheet metal without distortion or deformed edges. It also provided the flexibility to switch between different punch tools mid-program, which was essential for executing both large and small cutouts in a single pass.

Assembly and Strength

With the panels prepped, we moved to assembly. We used spot welding to secure each, with the full seams being welded out. Once assembled, surface finishing was the final step. Welds were ground smooth. Raw edges were deburred. The entire piece was cleaned and prepped for coating. This attention to detail is what turns a rough fabrication into something that looks like a designer piece.

Why This Project Stands Out

- Custom perforations highlight the fire and cast patterned light

- Structural design built for long-term outdoor use

- Seamless fabrication from raw material to finished piece

- Finished in-house with heat-resistant powder coating

We love bringing creative ideas like this to life. If you’ve got a design in mind or need help making it happen, we’re ready to help. Get in touch with our qualified team and let’s talk about your next custom fabrication project.