A Brief History on Custom Metal Fabrication

Metal working is a very old art form. It’s an interesting process that has changed a lot over time, and this blog goes into some details about the biggest changes thus far, as well as

Think You Know Metal? Think Again

Metal fabrication is an in-depth and sometimes complicated process, and metals in general aren’t as straightforward as they seem.

Metal as Art

In our last blog we talked about all the different ways custom fabricated metal can liven up your home. Metal pieces are a functional and aesthetic addition to indoor and outdoor spaces alike, providing a

All About CNC Machining with Acorn Metal

CNC machining is an innovative process that has revolutionised modern manufacturing and productivity. Referring to computer numerical control machining, the process utilises pre-programmed computer software that controls the precise and deliberate movement of different tools

How to Choose the Best Metal Fabrication Team for Your Project

When it comes to metal fabrication, expertise and technical skill makes all the difference. Whether you need to create a single one-off prototype or a series of mass produced components, a good metal fabrication team

Turning Drawings and Designs into Reality

All good products, inventions and machinery begin with dreams, visions and drawings. From the latest innovative tech through to big infrastructure developments, it all begins with a concept.

What to Look for When Choosing a Steel Fabrication Company

Steel is one of the most heavily used materials in industries across the world. From creating components for transport and infrastructure to developing the building blocks for innovative new tech, steel powers business growth and

Metal Fabrication in Everyday Life

Next time you wander through a city, take a good look around. From skyscrapers and trains through to cars and even mobile phones, metal is all around us.

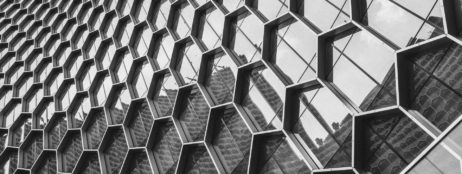

Applications that Require Metal Sheet Perforation

Perforated metal is where a sheet of metal is punched with a repeated pattern of holes. Staggered or in straight rows, holes sizes can vary from round to square, slotted, hexagonal and more.

Aluminium Bending Process

A perfectly curved piece of metal is a beautiful sight to behold. Sometimes, like balustrading, it’s for show and safety while other examples of aluminium bending serve structural and/or artistic purposes. Having met and surpassed

What we need to Know about Perforated Aluminium

Found in the clay mineral bauxite, aluminium is a relatively new discovery in human history. It was produced for the first time in 1824 thanks to the invention of electricity which allowed scientists to break

Maximising Your Space With Metal Fabrication

The industrial design interior trend is alive and well in Perth and abroad. Room dividers are just one example of the ways fabricated metal is being used in modern homes for fantastic effect. The great